Automatic Ribbon Cutter Machine: Precision And Speed For Your Craft

Think about all the times you've needed ribbons cut just so, perhaps for gift wrapping, crafting projects, or even a big event. It's a task that, while seemingly simple, can become quite a chore when you need many pieces, all exactly the same length. Getting those clean, consistent cuts by hand, over and over, is that a bit of a challenge, you know?

For many, this repetitive work often means aching hands, uneven edges, and a lot of wasted time. Whether you're a small business owner preparing custom orders or someone who loves to make things, the effort involved in precise ribbon cutting can sometimes slow you down. It's something that, honestly, takes away from the joy of creating.

But what if there was a way to make this process much, much easier? What if you could get perfectly cut ribbons, quickly and without any fuss? That's where an automatic ribbon cutter machine comes into the picture, offering a pretty clever solution to a common problem. It's a device that, in a way, takes the manual work right out of your hands.

- The Banyan Live West Palm Beach

- Matt Walker Mx

- Street Of Dreams 2024

- Trapstation Weed Packaging

- Super Mrkt Los Angeles

Table of Contents

- What is an Automatic Ribbon Cutter Machine?

- Who Benefits from Automated Ribbon Cutting?

- Types of Automatic Ribbon Cutter Machines

- Key Features to Look For

- Setting Up Your Machine

- The Impact on Efficiency and Creativity

- Frequently Asked Questions

What is an Automatic Ribbon Cutter Machine?

An automatic ribbon cutter machine is a specialized piece of equipment that, quite simply, cuts ribbons to specific lengths without a person needing to do each cut by hand. You feed the ribbon in, set your desired measurements, and the machine does the rest. It's really that simple, in some respects.

These machines are, you know, a very clever blend of mechanical and electronic parts, all working together to perform a very precise task. They are designed to handle various ribbon types, from delicate satin to sturdy grosgrain, delivering clean edges every single time. It's a tool that takes a lot of guesswork out of your projects.

The core idea behind these machines is to make repetitive cutting tasks much quicker and more reliable. For anyone who deals with large quantities of ribbon, it's a pretty essential item. So, it's not just about cutting, but about making your work flow better, too.

- Ts Kristen Kraves

- Marina City Club Photos

- Long Branch Volleyball

- Adam Ross Basketball

- Seven Points Uptown

Understanding "Automatic"

When we talk about something being "automatic," what does that truly mean for a machine like this? Well, according to "My text," something automatic has "the capability of starting, operating, moving, etc., independently." This means the machine can, you know, perform its job without a person constantly guiding its every move.

It's "performed from force of habit or without conscious thought" for the machine itself, meaning once you set it up, it just keeps going. An "automatic machine or device is able to operate independently of human control," which is a key point here. It acts "in a manner essentially independent of external influence or control," doing its work on its own.

"Automatic refers to a process or device that operates independently without any form of human intervention," as "My text" explains. This machine has "controls that allow something to work or happen without being directly controlled by a person." So, you set the length, press a button, and it takes over, cutting many ribbons very quickly. It's pretty much self-operating, which is a significant help, isn't it?

How They Operate

Most automatic ribbon cutters work by pulling ribbon from a spool, measuring it to a preset length, and then cutting it. This process happens very quickly, one piece after another. It's a rather smooth operation, you know.

The machine uses sensors to track the ribbon's movement and ensure each piece is the exact size you need. A blade, which might be hot or cold depending on the model, then makes a clean cut. Some models even seal the edges as they cut, which is a neat feature for preventing fraying, especially with satin or delicate materials.

You typically load a roll of ribbon onto a spindle, feed the end through a guide, and then use a control panel to input your desired length and quantity. The machine then, you know, starts its work, delivering a pile of perfectly uniform ribbon pieces. It's quite efficient, actually.

Who Benefits from Automated Ribbon Cutting?

A wide range of people and groups can really get a lot out of using an automatic ribbon cutter machine. It's not just for big factories, you know. Anyone who regularly needs precise, repeatable ribbon cuts will find these machines incredibly useful. They simplify tasks that can otherwise be quite time-consuming.

Consider small businesses that offer custom gift wrapping services or craft unique items for sale. For them, consistency and speed are pretty important. An automatic cutter helps them keep up with orders and maintain a high standard of quality. It's a tool that, in a way, supports their creative output.

Even individuals who enjoy extensive crafting as a hobby might find one of these machines a good addition to their workspace. If you're making many bows for a charity event or preparing decorations for a large family gathering, it can save you a lot of effort. So, it's about making your projects more enjoyable, too.

For Businesses and Makers

Small businesses, like those selling handmade jewelry, personalized gifts, or custom apparel, often use ribbons for packaging and presentation. An automatic ribbon cutter machine helps them create a professional, consistent look for every single product. This consistency, you know, helps build a strong brand image.

Event planners and florists also benefit immensely. Imagine needing hundreds of identical ribbon pieces for wedding decorations or floral arrangements. Doing that by hand would take hours, maybe even days. With a machine, it's done in a fraction of the time, freeing them up for other important tasks.

Craft supply companies and even small-scale manufacturers who use ribbon as part of their products can speed up their production lines significantly. It's a tool that, honestly, helps them manage their workload better and deliver orders more quickly. They can, you know, really boost their output.

Common Challenges Solved

One of the biggest problems these machines solve is inconsistency. When you cut ribbons by hand, even with a ruler, slight variations in length and angle are pretty common. This can lead to wasted material and a less polished final product. An automatic machine eliminates this human error, providing perfectly uniform pieces every time, which is very helpful.

Another major challenge is time consumption. Cutting hundreds or thousands of ribbon pieces manually is incredibly slow and tedious. It ties up valuable time that could be spent on more creative or income-generating activities. The machine, you know, handles this repetitive work, freeing up your hands and your schedule.

Finally, hand fatigue and potential injuries from repetitive cutting are real concerns for those who do this work often. An automatic cutter removes the need for constant gripping and snipping, making the process much safer and more comfortable. So, it's about looking after your well-being, too, in a way.

Types of Automatic Ribbon Cutter Machines

Not all automatic ribbon cutter machines are exactly alike. They come with different cutting mechanisms, each suited for particular types of ribbon materials and purposes. Knowing the differences can help you pick the right one for your needs, you know.

The choice often depends on the kind of ribbons you'll be working with most often and whether you need the edges sealed to prevent fraying. Some materials, for instance, react better to heat, while others are fine with a simple cold cut. It's a consideration that, honestly, makes a difference.

Understanding these variations is pretty important for making a good decision. Each type has its own strengths and is designed to handle specific tasks efficiently. So, let's look at the main kinds, shall we?

Hot Knife Cutters

Hot knife cutters use a heated blade to cut and seal the ribbon's edges at the same time. This is particularly good for synthetic materials like satin, nylon, or polyester, which tend to fray easily. The heat melts the fibers, creating a clean, sealed edge that won't unravel, which is a very useful feature.

This method provides a very neat finish, making it popular for items where a professional look is essential, like high-end packaging or apparel tags. The heat also helps prevent the ribbon from slipping during the cut, ensuring greater accuracy. So, for those materials, it's a pretty ideal solution.

However, hot knife cutters are not suitable for natural fibers such as cotton or linen, as the heat would simply burn them, creating a messy edge and a potential fire hazard. You know, it's important to use the right tool for the right material.

Cold Knife Cutters

Cold knife cutters use a sharp, unheated blade to cut through the ribbon. These are versatile and can be used for a wider range of materials, including natural fibers, paper, and some synthetic ribbons where sealing isn't necessary or desired. They are, you know, a pretty straightforward option.

While they don't seal the edges, they provide a very clean, crisp cut, which is perfect for materials that don't fray easily or when the edges will be hidden, like inside a seam or under a knot. They are often less expensive and simpler to maintain than hot knife models.

If you're working with a variety of materials and don't always need a sealed edge, a cold knife cutter might be a very practical choice. It's a good general-purpose machine, honestly, for many different projects.

Ultrasonic Cutters

Ultrasonic cutters are a more advanced type of machine that uses high-frequency vibrations to cut and seal materials. Instead of heat or a sharp blade, these machines create a very precise separation by vibrating the material at an ultrasonic frequency. This method is, you know, quite innovative.

They offer incredibly clean, sealed edges without the heat marks that hot knives can sometimes leave, making them ideal for very delicate or high-quality synthetic ribbons. They are also very precise and can handle intricate cuts with ease. This technology is, honestly, at the higher end of the spectrum.

While often more costly, ultrasonic cutters provide the best of both worlds: a sealed edge with exceptional precision and no burning. They are typically found in industrial settings or for specialized applications where perfection is paramount. So, for very specific needs, they are a pretty good option.

Key Features to Look For

When you're thinking about getting an automatic ribbon cutter machine, there are several features that are pretty important to consider. Not all machines are created equal, and what works well for one person might not be the best for another. You know, it's about finding the right fit.

Paying attention to these details can help you choose a machine that will truly meet your needs and be a good investment. It's not just about the price tag, but about the machine's capabilities and how it will fit into your workflow. So, let's look at some of the things that really matter.

Consider what types of ribbons you use most often, how many pieces you need to cut regularly, and what kind of finish you require. These questions will, honestly, guide you toward the features that are most important for your particular situation.

Adjustable Lengths and Speeds

A good automatic ribbon cutter machine should allow you to easily set and adjust the cutting length. Look for models with a clear digital display and simple controls for inputting measurements. This flexibility is, you know, pretty essential if you work with various projects that require different ribbon lengths.

The ability to adjust the cutting speed is also a valuable feature. For delicate materials, a slower speed might be needed to ensure a clean cut, while for high-volume tasks with sturdy ribbons, a faster speed will boost your productivity. It's about having control over the process, which is very helpful.

Some machines even offer memory functions, allowing you to save frequently used lengths and quantities. This can be a huge time-saver if you often repeat the same cutting jobs. So, look for that kind of convenience, too.

Material Compatibility

As we talked about earlier, different cutting methods work best with different materials. Before you buy, check what types of ribbons the machine can handle. If you work with both natural and synthetic ribbons, you might need a cold knife cutter, or perhaps even two different machines, you know.

Some machines are designed specifically for narrow ribbons, while others can accommodate wider widths. Make sure the machine's maximum ribbon width matches or exceeds the widest ribbon you plan to cut. This detail, honestly, can make a big difference in how useful the machine is to you.

Consider the thickness of the materials as well. Some heavy-duty machines can cut through multiple layers or thicker materials, which might be a good feature if your work involves more than just standard ribbon. So, think about all the materials you might use.

Ease of Use and Safety

A machine that's easy to set up and operate will save you frustration and time. Look for intuitive controls, clear instructions, and simple ribbon loading mechanisms. You know, you want to spend time creating, not struggling with the equipment.

Safety features are also very important. Machines with enclosed blades, emergency stop buttons, and stable bases help prevent accidents. Always prioritize models that have good safety measures in place, especially if others will be using the machine. It's a consideration that, honestly, you shouldn't overlook.

A machine that's simple to clean and maintain will also serve you better in the long run. Easy access to cutting areas for clearing debris or replacing blades can make a big difference in the machine's lifespan and consistent performance. So, think about how simple it is to keep it running well.

Setting Up Your Machine

Once you get your new automatic ribbon cutter machine, setting it up correctly is the first step to getting great results. It's not a very complicated process, but taking a little time to do it right can save you a lot of hassle later. You know, a good start makes for a good finish.

Most machines come with clear instructions, and it's always a good idea to read them thoroughly before you begin. This will help you understand all the specific features and safety guidelines for your particular model. So, don't skip that part, honestly.

Proper setup ensures the machine works efficiently and safely, giving you those consistent, clean cuts you're looking for. It's about getting everything aligned so the machine can do its job without any hiccups.

Getting Started

First, find a stable, flat surface for your machine. It should be somewhere with enough space around it for the ribbon spool and for the cut pieces to collect. A good, steady base helps ensure accurate cuts, you know.

Next, carefully load your ribbon onto the designated spool holder. Make sure it's properly aligned and can unroll smoothly without snagging. Then, thread the ribbon through the machine's guides according to the instructions. This step is pretty important for consistent feeding.

Finally, plug in the machine and turn it on. Use the control panel to set your desired ribbon length and the number of pieces you need. It's a good idea to do a few test cuts with a scrap piece of ribbon first to make sure everything is calibrated correctly before you start on your main project. So, take your time with those initial steps.

Maintenance Tips

Keeping your automatic ribbon cutter machine in good shape will help it last longer and perform better. Regular cleaning is pretty important. Ribbon fibers and dust can build up around the blade and moving parts, which can affect cutting quality over time. You know, a clean machine works best.

Use a soft brush or compressed air to remove any debris from the cutting area and around the sensors. If your machine has a hot knife, make sure to clean any residue off the blade when it's cool. This helps keep the blade sharp and ensures clean seals.

Blades will eventually become dull and need to be replaced. Check your machine's manual for guidance on how often to replace the blade and where to purchase replacements. Keeping a sharp blade is essential for precise cuts and to prevent fraying. So, remember to keep an eye on that, too.

The Impact on Efficiency and Creativity

Bringing an automatic ribbon cutter machine into your workspace can truly change how you approach tasks involving ribbon. It's not just about getting things done faster; it's about freeing up your time and energy for more important or creative parts of your work. You know, it's a pretty big shift.

When the mundane, repetitive work is handled by a machine, you can focus on designing, planning, or adding those special touches that really make your projects stand out. This shift can lead to a significant boost in both your output and the quality of your finished items. It's a tool that, honestly, helps you be more productive and imaginative.

Consider the broader impact on your business or hobby. More efficient production means you can take on more orders, meet tighter deadlines, or simply enjoy your crafting without the tedious parts. So, it's about making your work life better, in a way.

Saving Time and Effort

The most obvious benefit of an automatic ribbon cutter machine is the incredible amount of time it saves. What might take hours of manual cutting can be done in minutes with a machine. This speed is pretty valuable, especially during busy periods or for large projects. You know, time is precious.

Beyond just speed, it also saves you physical effort. No more hand cramps or tired wrists from repeatedly squeezing scissors. The machine takes on the physical strain, allowing you to work longer and more comfortably. It's a relief, honestly, for anyone who does a lot of cutting.

This saved time and effort can be redirected to other areas of your business or creative pursuits. Perhaps you can spend more time on marketing, developing new product ideas, or simply relaxing. So, it's about optimizing your entire workflow, too.

Consistent Quality

One of the hallmarks of professional work is consistency, and an automatic ribbon cutter machine delivers this perfectly. Every single piece of ribbon will be the exact same length, with clean, uniform edges. This level of precision is very difficult to achieve by hand, especially for large quantities.

This consistent quality translates directly to a more polished and professional final product. Whether it's a beautifully wrapped gift, a perfectly uniform bow, or a precise embellishment, the consistent ribbon cuts contribute to a higher standard of craftsmanship. You know, details matter.

For businesses, consistent quality builds customer trust and enhances brand reputation. Clients will appreciate the attention to detail and the high standard of your work. It's a subtle but powerful way to show you care about what you do. Learn more about automatic ribbon cutting solutions on our site, and discover various ribbon materials that can be used with these machines.

Frequently Asked Questions

How accurate are automatic ribbon cutters?

Automatic ribbon cutters are designed for very high accuracy. They typically use precise measurement systems, often with digital controls, to ensure each ribbon piece is cut to the exact length you set. So, you can expect, you know, very consistent results, much more so than cutting by hand.

Can automatic ribbon cutters cut different materials?

Yes, many automatic ribbon cutters are versatile enough to handle a range of materials. However, the specific types of materials they can cut depend on the cutting mechanism. Hot knife cutters are best for synthetics like satin and polyester, while cold knife cutters work well for natural fibers, paper, and various fabrics. Ultrasonic cutters are, honestly, very good for delicate synthetics. It's important to check the machine's specifications for material compatibility.

Are automatic ribbon cutters worth it for small businesses?

For small businesses that regularly use ribbons for packaging, products, or events, an automatic ribbon cutter can be a very worthwhile investment. It saves a lot of time and effort, reduces material waste due to inconsistent cuts, and helps maintain a professional, consistent quality across all products. So, it can, you know, significantly boost efficiency and professionalism.

- Matt Weber Photographer

- Christmas Market Niagara Falls

- Black Wolf Harley Davidson Bristol Va

- Indie Sleaze Night

- Cole Young Metalwood

Ribbon Cutter Swallow Tail Machine, Ribbon Cutter Swallow Tail Machine

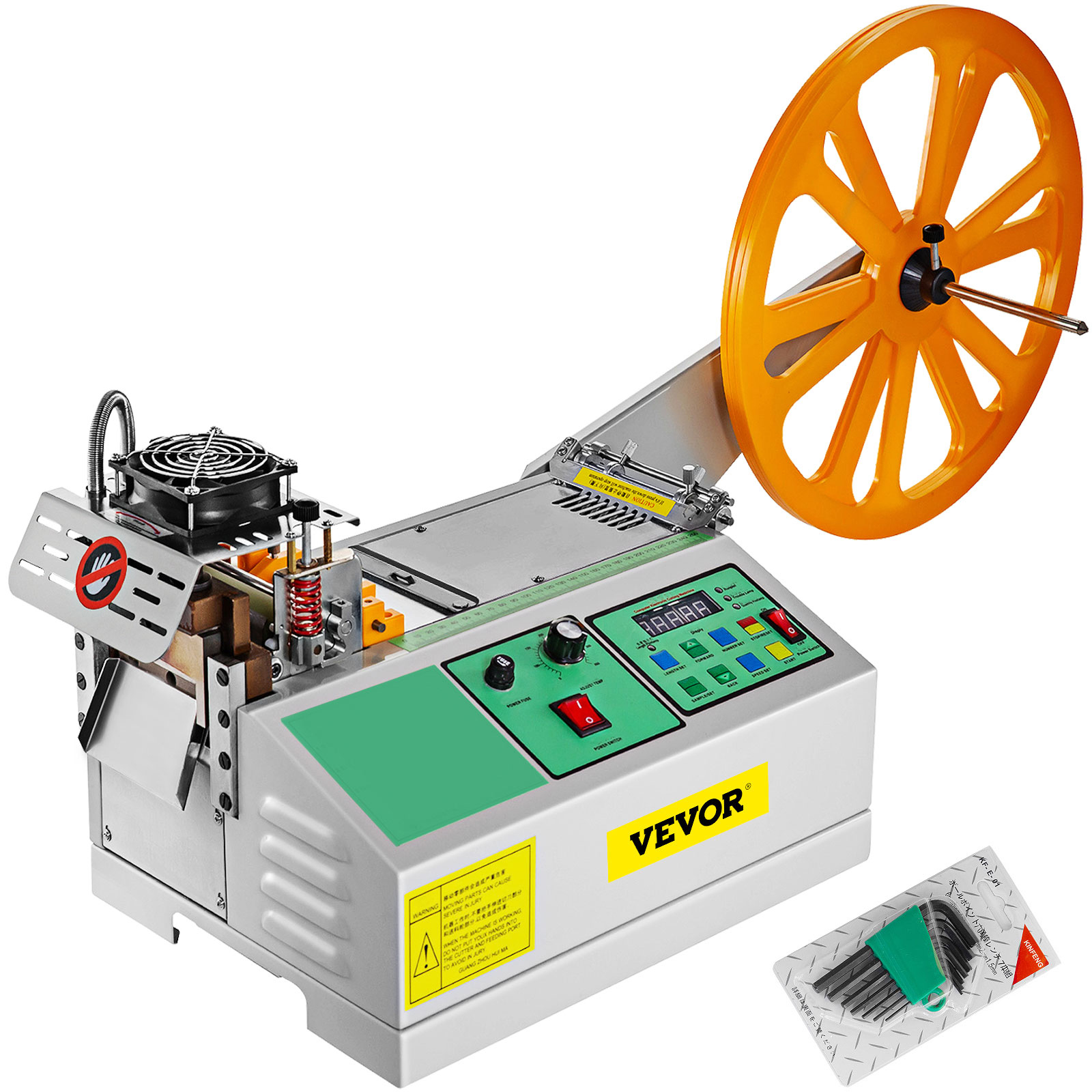

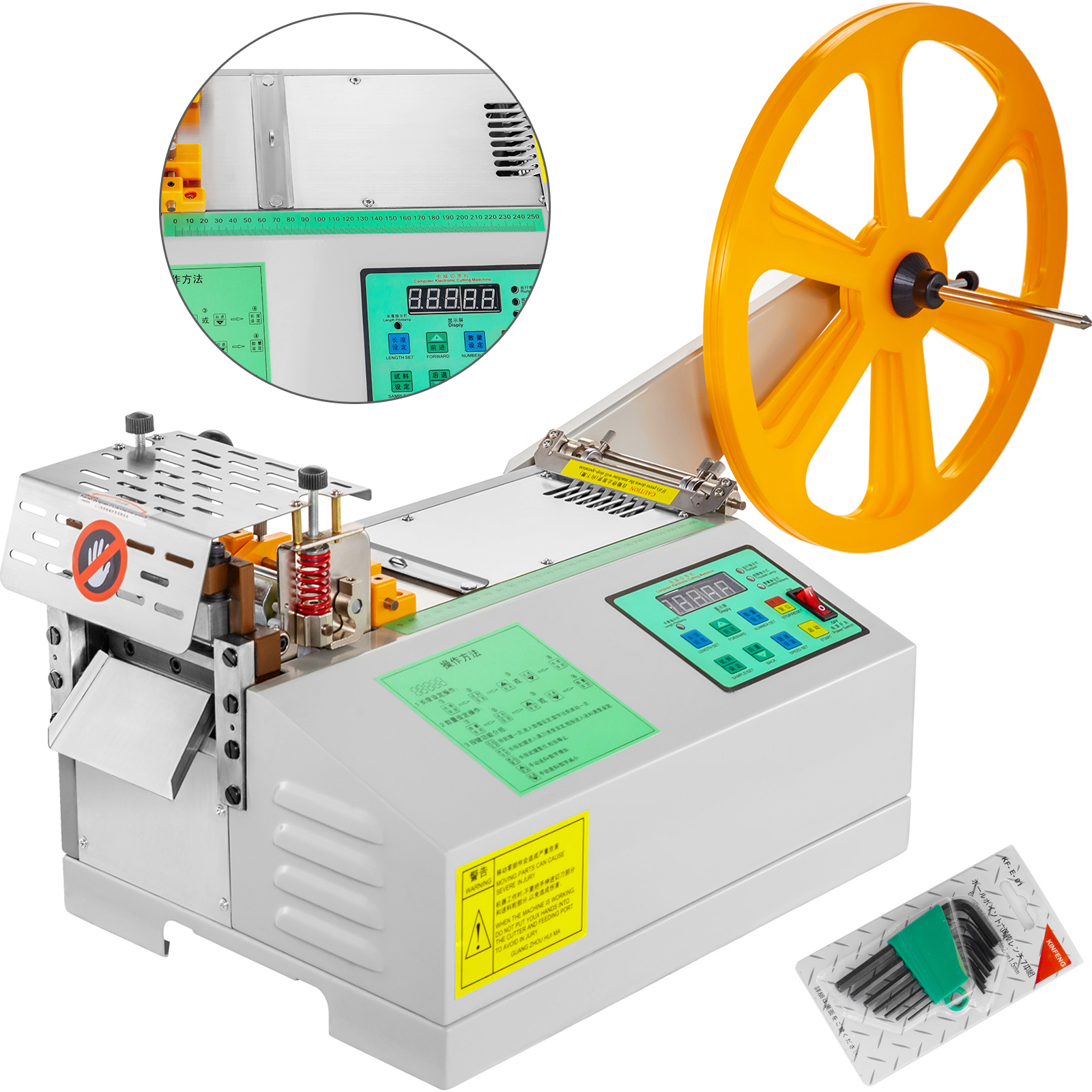

VEVOR Automatic Cold Tape Cutting Machine Digital Belt Cutter 95mm/3

VEVOR Automatic Hot and Cold Tape Cutting Machine Digital Belt Cutter